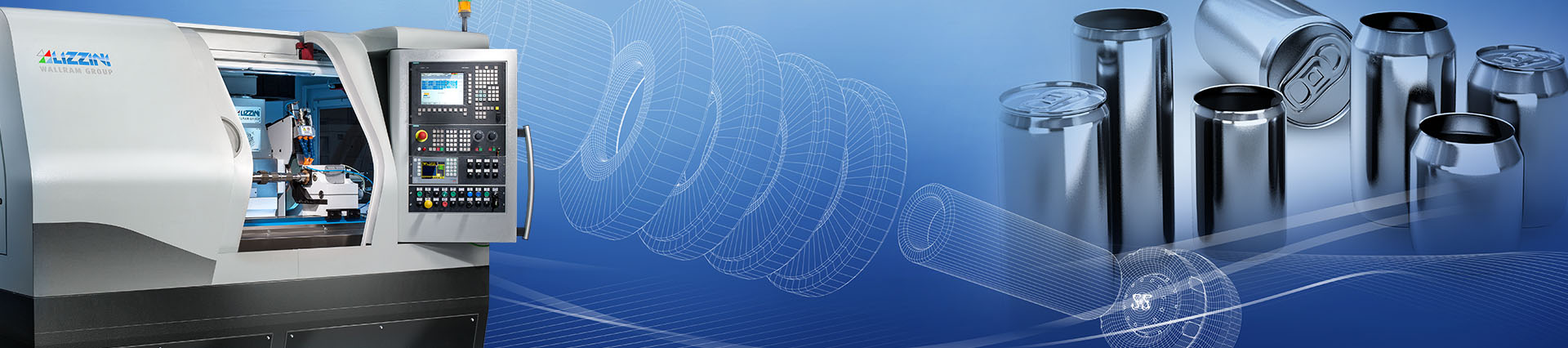

Can tooling

A large variety of metal packaging is available. Whether a two-piece or three-piece can, in the form of a tube, aerosol, or bottle: WALLRAM provides the right tools for the manufacturing process. Whether cupper press, bodymaker, or necker: WALLRAM tools can be found all over the world. The high quality and wear resistance of WALLRAM tools contribute to a reduction of production costs by extending the durability and reducing scrap. The comprehensive regrinding service increases the tool life cycle and, thus, supports sustainable and environmentally friendly production.